Thermoplastische Umformung

Wir geben Well- und Glattrohren aus Kunststoff ihre individuelle Form

Aufgrund unserer langjährigen Erfahrung haben wir einen hohen Spezialisierungsgrad für die thermoplastische Umformung von Kunststoffrohren erreicht. Wir haben einen leistungsstarken Systembaukasten entwickelt, der Ihnen Effizienz, Wirtschaftlichkeit und technisch einwandfreie Produktionsabläufe garantiert.

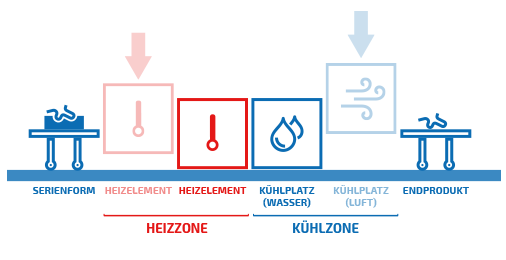

Schematische Darstellung des Systembaukastens

Weltweit vertrauen Kunden auf unsere Produkte.

Individuell geformte Kunststoffrohre von der Kleinauflage bis zur Serienproduktion. Das Leistungsspektrum der RBZ ermöglicht Ihnen eine standortungebundene eigene Herstellung inklusive Qualitätssicherung durch unsere Produktprüfverfahren.

Biegewerkzeuge, Tempersysteme und Prüflehren werden für Sie individuell bei uns hergestellt und bieten Ihnen im Gesamtumfang die Möglichkeit einer eigenen autarken Produktion Ihrer benötigten Kunststoffleitungen.

Biegewerkzeuge

Von der Konstruktion zur Serienform

Vom Prototypen bis zur Serienform fertigen wir Biegeformen aus Edelstahl für die thermoplastische Umformung von Well- und Glattrohren aus Kunststoff in einer optimierten Prozesskette. Die Weiterverarbeitung im RBZ-Tempersystem gewährleistet eine hohe Fertigungsgenauigkeit und effiziente Durchsatzgeschwindigkeit.

Unsere Leistungen im Überblick:

- Erstellung der Form- und Leitungsfolie

- Herstellung der Prototypenform

- Produktion der Serienform

Prototypenform

Anhand Ihrer Konstruktionsdaten erstellen wir die erste Prototypenform. Diese wird von uns gemessen und geprüft. Präzision ist hier maßgebend für unsere Arbeit.

Serienform

Nach abgeschlossener Prototypenphase und Erfüllung aller Qualitätskriterien, beginnen wir mit der Herstellung der Serienformen. Von Klein- bis Großserie, mit unseren Serienformen erreichen wir eine kontinuierliche Qualität aller Leitungen

Tempersysteme

Die modulare Bauweise des RBZ-Tempersystems garantiert eine optimale Integration in Ihre bestehende Produktionskette. Die zuverlässige Leistung auch bei hohen Produktions- und Durchsatzraten ermöglicht eine reibungslose, standortungebundene Herstellung individuelle geformter Kunststoffleitungen.

Exemplarische Darstellung! Eine Kombination von Wasser- und Luftkühlelementen ist in der Praxis nicht vorgesehen

Optimale Energieverteilung

Durch die getrennt von einander regelbaren Heizzonen ist eine optimale Verarbeitung der unterschiedlichen Leitungsmaterialien präzise realisierbar. Die RBZ-Tempersysteme überzeugen durch ihre hohe Wirtschaftlichkeit bei überaus geringen Verformzeiten.

Modulare Bauweise

Das RBZ-Tempersystem ist – abhängig von den gewünschten Anforderungen – in unterschiedlichen Ausführungen lieferbar.

Die Anzahl der Heizzonen sowie die Länge und der Verlauf der Kühlstrecke sind frei konfigurierbar. Die modulare Bauweise aus erprobten Systemkomponenten ermöglicht die optimale Integration in die Prozesskette.

RBZ Das Rohrbiegezentrum in Kassel

Ihr leistungsstarker Partner für:

Wassergekühlt

Schnelle und effiziente Kühlung durch Wasser sorgen für einen gleichmäßigen Kühlprozess

Luftgekühlt

Trockene Kühlung ohne Rückstände. Keine Zeitverluste gegenüber der Kühlung mit Wasser.

Leistungslänge

Durch die modulare Bauweise des RBZ-Tempersystems ist es möglich die Produktion an unterschiedlichsten Leistungslängen anzupassen.

Heizleistung Ofen

Unsere Öfen erreichen eine Heiztemperatur von 280 °C und können an unterschiedliche Materialeigenschaften angepasst werden.

Technische Daten (Beispiel)

Daten variieren je nach Bauart der Anlage.

MH 4ZHP

(MH 4 Zone Heat Process)

Ofen

Durchlassbreite 650 mm

Durchlasshöhe 1.100 mm

Haubenlänge 4.500 mm

Wirkzone 4.000 mm

Gesamtlänge 5.850 mm

Heizleistung 96 KW

Anzahl der Heizzonen 4

Kühlzone

Länge 1.500 mm

max. Leitungslänge 1.500 mm

Gesamtlänge 3.000 mm

Spezielle Anforderungen?

Kein Problem! Wir bauen Ihr individuelles Tempersystem.

Die modulare Bauweise des RBZ-Tempersystems ermöglicht uns auch individuelle Wünsche und spezielle Anforderungen an das System für unsere Kunden umzusetzen.

Wir beraten Sie kompetent zu Ihren Fragen und helfen Ihnen auch bei speziellen Anforderungen an das gesamte Tempersystem.