Thermoplastic forming

We give corrugated and smooth plastic tubes their individual shape

Due to our many years of experience, we have a high degree of specialisation in the following fields thermoplastic forming of plastic pipes reached. We have a powerful modular system which guarantees you efficiency, profitability and technically flawless production processes.

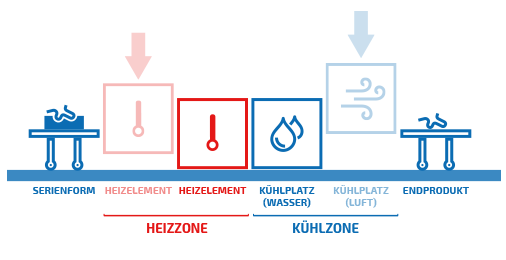

Schematic representation of the modular system

Worldwide customers trust in our products.

Individually shaped plastic pipes from small runs to series production. The range of services offered by RBZ enables you to Location-independent own production including quality assurance through our product testing procedures.

Bending tools, tempering systems and test gauges are manufactured individually for you by us and offer you the possibility of a own self-sufficient production of your required plastic pipes.

Bending tools

From design to series mould

From prototypes to series production we manufacture Bending moulds made of stainless steel for thermoplastic forming of corrugated and smooth plastic tubes in an optimized process chain. Further processing in the RBZ tempering system ensures high manufacturing accuracy and efficient throughput speed.

Our services at a glance:

- Production of form and line foil

- Production of the prototype mould

- Production of the series mould

prototype mold

Based on your design data, we create the first prototype mould. This is measured and checked by us. Precision is decisive for our work here.

series mould

After completion of the prototype phase and fulfilment of all quality criteria, we begin with the production of series moulds. From small to large series, with our series moulds we achieve a continuous quality of all cables.

Tempering systems

The modular design of the RBZ tempering system guarantees optimum integration into your existing production chain. Reliable performance, even at high production and throughput rates, allows for smooth, location-independent production individually shaped plastic pipes.

Exemplary presentation! A combination of water and air cooling elements is not intended in practice.

Optimum energy distribution

Through the heating zones can be controlled separately from each other an optimal processing of the different cable materials can be realized precisely. The RBZ tempering systems convince with their high profitability with extremely short deformation times.

Modular design

The RBZ tempering system is - depending on the desired requirements - available in different versions.

The number of heating zones as well as the length and course of the cooling section are freely configurable. The modular construction from proven system components enables optimal integration into the process chain.

RBZ The tube bending centre in Kassel

Your high - powered partner for:

Water cooled

Fast and efficient cooling with water ensures an even cooling process

Air cooled

Dry cooling without residues. No loss of time compared to cooling with water.

performance length

Thanks to the modular design of the RBZ tempering system, it is possible to adapt production to a wide range of output lengths.

Heating capacity stove

Our furnaces reach a heating temperature of 280 °C and can be adapted to different material properties.

Technical data (example)

Data vary depending on the type of system.

MH 4ZHP

(MH 4 Zone Heat Process)

kiln

passage width 650 mm

outlet height 1.100 mm

hood length 4.500 mm

effective area 4.000 mm

overall length 5.850 mm

heating capacity 96 KW

Number of heating zones 4

cooling zone

length 1.500 mm

max. cable length 1.500 mm

overall length 3.000 mm

Special requirements?

No problem. We build your individual tempering system.

The Modular design of the RBZ tempering system also enables us to implement individual wishes and special system requirements for our customers.

We advise you competently to your questions and help you also with special requirements for the entire tempering system.